The Function of CNC Machining Providers in Modern Manufacturing and Design Solutions

CNC machining services have actually come to be essential in modern production and design. They provide precision and effectiveness, enabling the creation of facility parts with marginal human oversight. This innovation not just minimizes production time and prices yet likewise resolves the enhancing demands of different markets. As technology progresses, the landscape of CNC machining is readied to alter even more - cnc turning service. The ramifications of these growths warrant closer exam

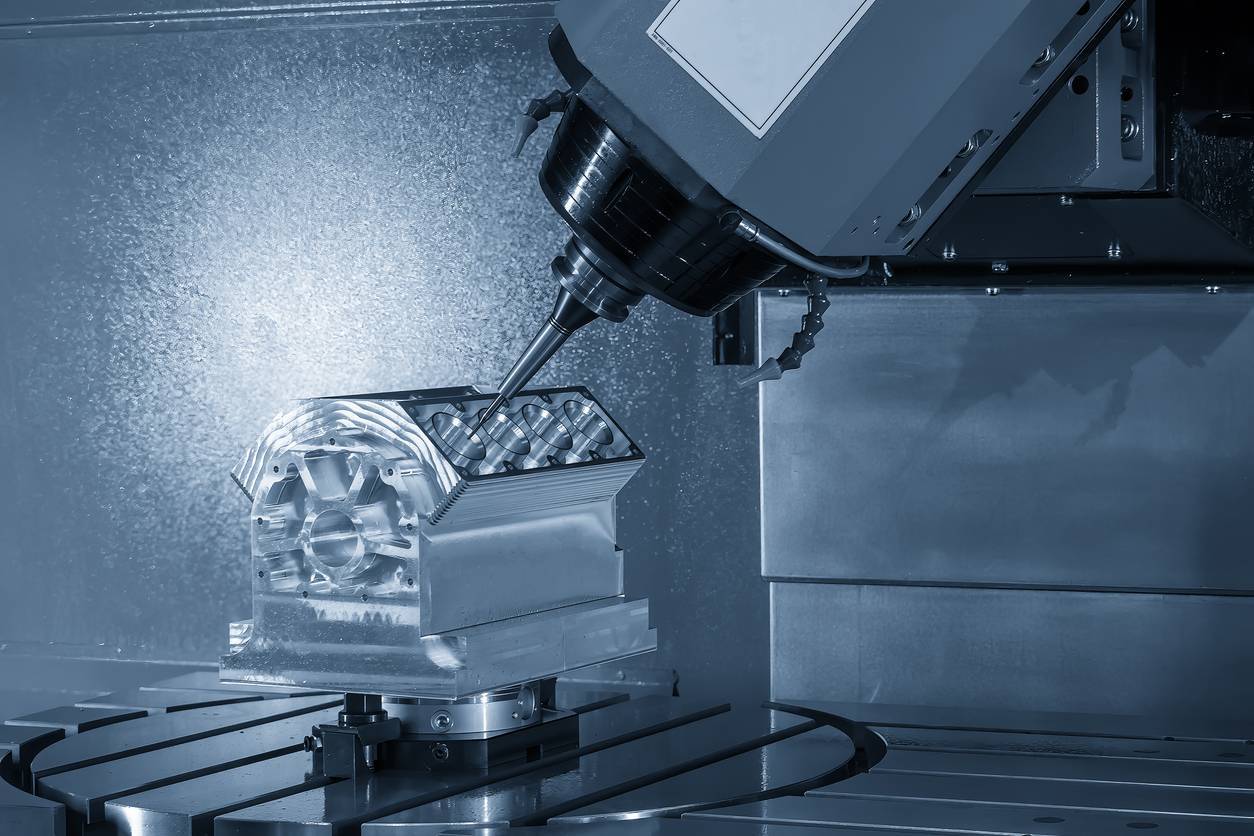

Comprehending CNC Machining: An Introduction

CNC machining, a cornerstone of modern-day production, involves making use of computer-controlled tools to specifically cut and shape materials. This innovation integrates sophisticated software program and machinery to automate the manufacturing procedure, making sure high precision and performance. CNC, which means Computer system Numerical Control, allows drivers to input comprehensive requirements that assist the equipment in implementing complex layouts.

Numerous materials, consisting of plastic, wood, and metal, can be machined, making CNC flexible across different markets. The process starts with a digital version, generally developed making use of CAD software program, which is translated right into equipment language for execution.

CNC machining encompasses numerous techniques, such as milling, transforming, and drilling, each suited for particular applications. The fostering of CNC technology has transformed manufacturing capabilities, enabling makers to create detailed get rid of very little human intervention. As an outcome, it has actually become a vital element in markets varying from aerospace to auto.

Benefits of CNC Machining in Production

CNC machining supplies considerable benefits in production, particularly with respect to accuracy and precision, which improves product top quality. Furthermore, it is cost-efficient, enabling decreased manufacturing prices while maintaining high requirements. Its adaptability in dealing with different materials better underscores its worth in contemporary production procedures.

Precision and Accuracy

In modern production, precision and accuracy are critical, and progressed machining strategies play an essential function in achieving these goals. CNC machining solutions give exceptional consistency in production, allowing manufacturers to produce complex parts with specific specifications. By making use of computer system numerical control, these makers eliminate human mistake, making sure that each part fulfills strict tolerances. The repeatability of CNC machining allows organizations to produce huge amounts of the same products without sacrificing quality. Furthermore, progressed software made use of in CNC procedures enables fast modifications and intricate layouts, boosting flexibility in the production process. Ultimately, the precision and precision used by CNC machining considerably add to enhanced item integrity and performance, promoting innovation and satisfying the ever-evolving needs of various industries.

Cost-Effectiveness

Cost-effectiveness stands apart as a substantial advantage of CNC machining in the manufacturing industry. By automating the machining procedure, companies can minimize labor expenses and lessen human error, which causes greater performance. CNC machines operate constantly and can produce components at a faster rate than conventional techniques, ultimately decreasing manufacturing prices. Additionally, the accuracy supplied by CNC machining lowers material waste, ensuring that resources are made use of efficiently. Therefore, organizations can accomplish higher profit margins while keeping premium criteria. The ability to produce complex designs with very little configuration time more boosts price efficiency. Generally, CNC machining presents an engaging remedy for suppliers seeking to enhance their procedures and stay affordable in a demanding market.

Convenience in Products

Adaptability in materials is a characteristic of modern CNC machining, permitting manufacturers to collaborate with a large variety important, including metals, plastics, timber, and composites. This capability allows the production of diverse parts tailored to specific application demands. For example, aluminum and stainless-steel can be machined for robust industrial parts, while plastics are suitable for corrosion-resistant and light-weight applications. Timber machining accommodates the furniture and ornamental markets, while composites provide strength-to-weight benefits in aerospace and vehicle sectors. The capacity to change between materials without considerable reconfiguration enhances workflow effectiveness and lowers lead times. Eventually, this versatility equips makers to innovate and satisfy evolving market demands, solidifying CNC machining's duty as a keystone of modern-day design solutions.

Key Industries Benefiting From CNC Machining Providers

CNC machining solutions play a crucial role in numerous essential sectors, particularly aerospace and protection, in addition to automotive component production. These industries rely upon the accuracy and performance of CNC technology to satisfy stringent high quality and safety and security standards. The capacity to generate intricate parts with tight tolerances positions CNC machining as a crucial tool in modern manufacturing.

Aerospace and Defense Applications

In the high-stakes domain of aerospace and precision, defense and dependability are vital, making CNC machining services vital. These services allow the production of intricate parts with exacting resistances, necessary for airplane, satellites, and armed forces tools. CNC machining facilitates the creation of lightweight yet durable components, commonly making use of innovative products such as titanium and carbon fiber. The ability to rapidly model and manufacture elements accelerates the advancement cycle, ensuring that vital systems are both reliable and efficient. CNC technology boosts repeatability, minimizing the danger of human error and guaranteeing regular high quality across large manufacturing runs. As the aerospace and protection industries progressively embrace automation, CNC machining services will remain to play a crucial function in meeting stringent regulative criteria and operational needs.

Automotive Component Production

The automotive industry, just like aerospace and defense, depends greatly on precision engineering to fulfill the demands of modern-day production. CNC machining solutions play an essential duty in producing premium automobile components, such as engine components, transmission housings, and customized fittings. These services allow suppliers to attain limited resistances and complex geometries, essential for enhancing car performance and safety and security. The capacity to promptly adapt designs and create models via CNC machining increases innovation within the sector. In addition, the scalability of CNC machining allows for both little set manufacturing and large production, accommodating diverse market needs. As electrical and self-governing automobiles gain traction, the reliance on CNC machining is poised to grow, better strengthening its value in automobile element production.

The CNC Machining Process: From Layout to Production

Transforming a digital design right into a concrete product includes a collection of accurate action in the CNC machining procedure. Engineers make use of computer-aided style (CAD) software program to produce find out here now an in-depth electronic model of the desired component. This version is then converted right into a style compatible with CNC makers, generally via computer-aided manufacturing (CAM) software program. The CNC machine analyzes this information to assist its operations.

When the layout is prepared, the selected product is safeguarded in the CNC device. The machining procedure begins, involving various techniques such as milling, turning, and boring, where devices eliminate product to shape the part according to specifications. Throughout production, the maker continually monitors and adjusts for precision, assuring the end product fulfills the style criteria.

After machining, parts undertake ending up procedures such as sanding or finish to improve capability and appearances. This methodical technique warranties that high-grade components are created effectively and precisely.

Innovations and Trends in CNC Machining Technology

As improvements in modern technology continue to form the manufacturing landscape, CNC machining is experiencing considerable developments that improve efficiency and accuracy. One popular fad is the assimilation of expert system and maker learning, enabling flexible machining processes that maximize device paths and minimize cycle times. In addition, the adoption of sophisticated products, such as composites and light-weight alloys, expands the abilities of CNC machines, permitting the production of intricate geometries with greater strength-to-weight ratios.

In addition, cloud computer and IoT (Internet of Things) innovations facilitate real-time tracking and data analysis, leading to predictive upkeep and lessening downtime. Automation with robotics is likewise ending up being progressively common, simplifying workflows and boosting security in production settings. Lastly, the increase of 5-axis machining provides exceptional flexibility and precision, making it possible for the creation of intricate parts in a single configuration. These innovations collectively place CNC machining at the leading edge of modern-day production services.

Future Expectation: The Advancing Duty of CNC Machining in Design Solutions

CNC machining is poised to play a progressively important role in design remedies as sectors welcome innovative technologies and advancing market demands. As automation and wise production gain grip, CNC machining solutions are expected to integrate with Net of Things (IoT) devices and artificial knowledge (AI) to improve accuracy and effectiveness. This integration will certainly permit real-time surveillance and anticipating upkeep, minimizing downtime and improving manufacturing performance.

Moreover, the rise of personalized production will demand more adaptable CNC systems capable of adapting to little set production with fast turnaround times. Sustainability concerns will certainly likewise drive innovations in CNC machining, triggering the growth of environmentally friendly materials and procedures.

Inevitably, CNC machining will certainly proceed to progress, addressing the complexities of contemporary engineering difficulties while offering scalable and economical options that satisfy the diverse requirements check that of markets ranging from aerospace to healthcare.

Often Asked Inquiries

What Materials Can CNC Machining Work With?

CNC machining can deal with a variety of materials, consisting of steels like aluminum, titanium, and steel, in addition to plastics such as acrylic and nylon. In addition, timber and compounds are additionally suitable for CNC machining processes.

Just how Do I Select a CNC Machining Provider?

When choosing a CNC machining company, one ought to consider their experience, tools high quality, material capabilities, client reviews, turnaround times, and prices. A thorough comparison ensures the chosen supplier satisfies details task requirements successfully.

What Is the Regular Turnaround Time for CNC Machining Projects?

Common turnaround times for CNC machining jobs vary, typically ranging from a few days to several weeks, depending upon project complexity, material schedule, and the company's work. Timelines must be validated directly with the selected copyright.

Are There Minimum Order Quantities for CNC Machining Solutions?

Just How Does CNC Machining Ensure Precision and Precision in Manufacturing?

CNC machining guarantees precision and precision through computer-controlled operations, which lessen human mistake. Advanced software and top notch machinery assist in exact measurements, consistent replication, and complex designs, causing premium parts that satisfy rigid specifications and tolerances.

CNC machining, a cornerstone of contemporary production, entails the use of computer-controlled devices to exactly cut and shape materials. CNC machining solutions give unparalleled uniformity in manufacturing, permitting makers to develop complicated parts with precise specs. CNC machining solutions play an important function in various essential sectors, particularly aerospace and protection, as well as automotive component manufacturing. Furthermore, the scalability of CNC machining enables for both small batch manufacturing and large manufacturing, providing to varied market demands. As automation and wise production gain traction, CNC machining solutions are anticipated to integrate with Web of Things (IoT) devices and synthetic intelligence (AI) to enhance precision and effectiveness.